The best road bottom bracket upgrades: stainless steel and ceramic bearings for silky smooth miles

Tested and rated the best bottom brackets available aftermarket for staying creak-free and finding extra watts!

Finding the best bottom bracket for your road bike can lead to many frustrating hours spent staring at a screen, but let me reassure you that even after many years as a mechanic, it still drives me nuts, too. That is why I have created this guide to the best bottom brackets for road bikes, in which I have tested and rated six of the best upgrade options.

If you are lucky enough to own one of the best road bikes, you might be looking to save weight and watts. In that case, I have included some of the best ceramic bearing options, like the CeramicSpeed Uncoated BB. It is arguably the original and, I believe, the best bottom bracket upgrade available, but it comes at a cost.

It's worth noting that some of the best bottom brackets for road bikes are not necessarily the most expensive. Plenty of high-quality and affordable options are available. For example, the C-Bear Ceramic or Wheels Manufacturing ACB steel bearing options are affordable replacements, priced around £100/$125.

Synonymous with high-quality bearings, Chris King products frequently outlast the rest of the bike. A great warranty, proven heritage, serviceability, and beautiful attention to detail go a long way towards offsetting the outlay.

If high-quality ceramic bearings and excellent customer service aren't enough for you, then C-Bear's massive range of BB sizes might clinch the deal. Every option is made from scratch, so there are no washers, spacers or adapters to creak or drag.

The perfect combination of high quality and a reasonable price makes Kogel's BB a worthwhile option. All common-size options are available, but the colour is limited to black, which won't be a deal-breaker for most.

Another extremely high-quality option, the in-house stainless steel bearings will last a very long time with a bit of TLC occasionally. There are numerous colours to choose from, and Chris King claims that the bearings will wear in and become smoother with age.

If there is one available in the size you need, it's hard to look beyond Hope's offering unless you are committed to gaining every last watt. They last a long time, are built to withstand the rigours of the UK weather, and are remarkably reasonable in price.

Wheels Manufacturing BBs screw together inside the frame, so they can often solve the issue of creaking Pressfit units. They are designed to last, and perhaps sacrifice a slight amount of friction to keep the bearings well-sealed and dirt-free, making them a great year-round choice.

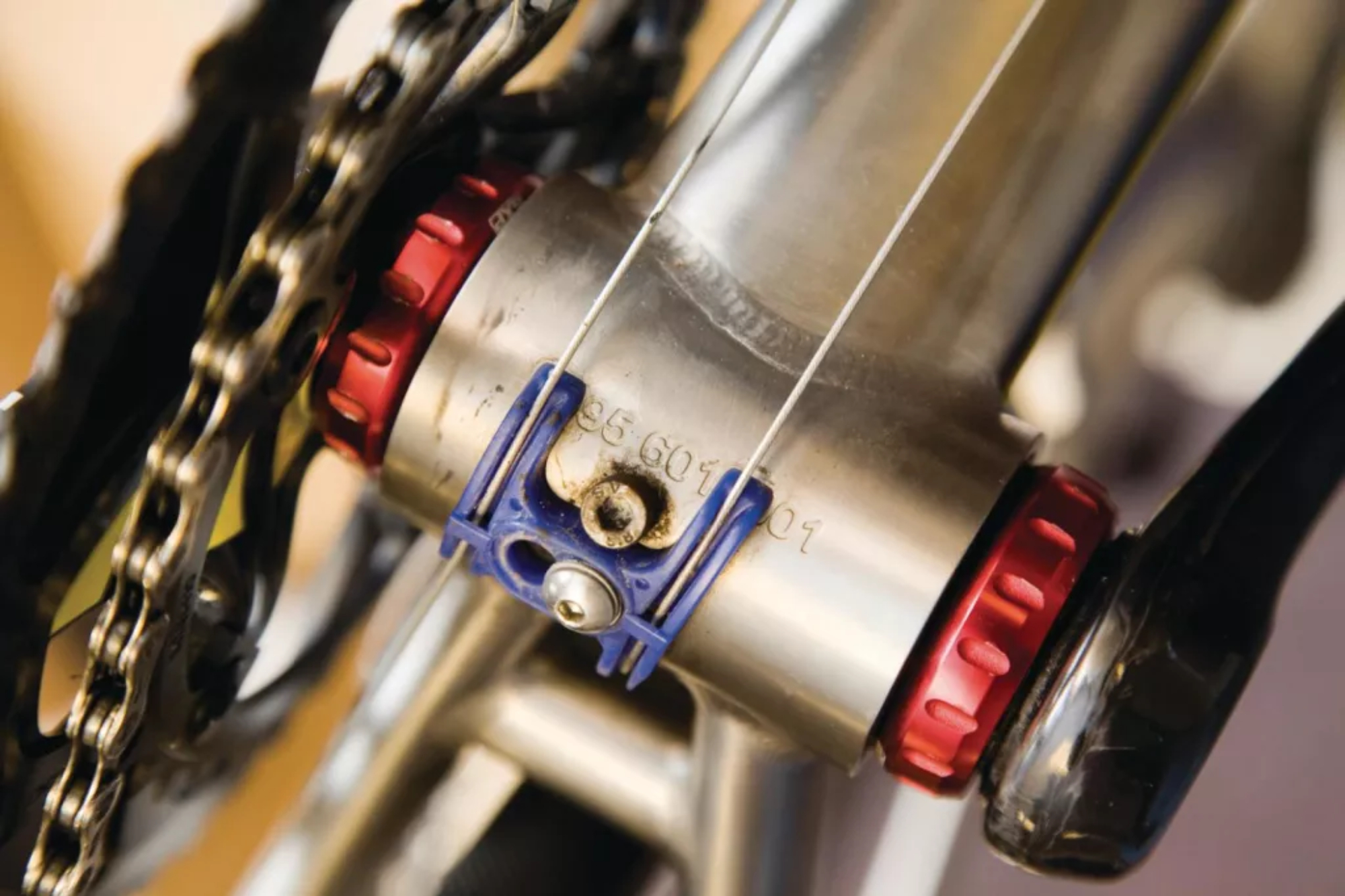

The instantly recognisable red anodized cup of CeramicSpeed bottom brackets

Our expert review:

A name which is synonymous with high-quality bearings and most people’s first thought when discussing upgrades. CeramicSpeed makes a unit to fit almost any frame/crank combo. The standard Un-coated version of the BB features ceramic bearings which can be filled with your choice of grease, to suit the riding you’ll be doing.

Long-life grease extends the service period of the BB and is best for mixed weather and gravel, whilst the Performance grease is great for TT bikes and summer road bikes – if you have your bike serviced regularly it’s possible to swap grease depending on the season.

CeramicSpeed does make a point of saying that a ceramic BB doesn’t mean you can neglect the servicing like many people assume – the units still need the same care and attention that steel bearings require, but ceramic units will indeed wear less than steel units when cared for properly.

My test CeramicSpeed unit is actually a standard version that I bought several years ago now and is just about due to outlast the bike it’s been in, and it’s four year warranty (CeramicSpeed also offer a coated version with a lifetime warranty). Most of the time I’ve run performance grease in the unit and I’ve done a very simple service of it twice a year. It’s still noticeably easier to spin than my other bikes and I’ve experienced zero creaks/noise. It’s true that this has been my summer road bike for the last three years but I’ve ridden in all weathers and the BB has never skipped a beat. It's been a joy to ride, making me feel slightly better about the initial cost of fitting.

Likely the quietest BB on the market

Our expert review:

Similarly to CeramicSpeed, C-Bear produces a BB for just about any combination of frame/groupset and the chart on the website is very easy to use to help you pick the right unit. You simply identify what BB shell your frame is and what spindle/crankset you have and C-Bear will tell you which BB fits in between the two. I fitted a threaded unit to one of my bikes six months ago and have fitted many customer units in the last three years. I’ve been really impressed by the aftercare both from Belgium and from the UK importer.

When I started writing this review I realised that after six months I haven’t actually needed or even thought about servicing the BB. I wouldn’t claim it’s a fit-and-forget unit as it will need servicing just like a steel BB at some point, but given that we’ve had a relatively mild spring in the UK I’ve not needed to worry. The BB still feels silky smooth and silent - as I mentioned in the introduction, this is a big factor in making me want to ride my bike.

Such amazing value you can afford to keep a spare for less than one CeramicSpeed

One of the reasons that the C-Bear unit is so quiet is that they’ve completely done away with all loose parts such as wave washers, spacers and adapters. This is critical in the reduction of noise and can only be achieved when a brand like this makes a BB option specific to each frame/crank option. It’s a huge amount of work on their part and more than justifies the price tag in my opinion.

The price itself is one of the selling features of C-Bear – depending on the option you go for the C-Bear units can be half the price of CeramicSpeed. It's certainly a significant difference and quite probably a major consideration to many riders looking to upgrade. It puts C-Bear in the realms of some of the more expensive OE brands and packs an impressive punch.

Our expert review:

A relative newcomer to the market, Kogel quickly received a reputation for high-quality kit at a fairly affordable price. Branding is clean, all the BBs are finished in satin anodizing and the product is highly functional rather than being offered in lots of garish colours – it’s very much there to do the job.

As with my Chris King unit, my Kogel BB has been on a few different bikes over the years and has been serviced accordingly. I have noticed that the Kogel unit requires a tiny bit more attention than the others I’ve tested but still well within the bounds of a regular service. Interestingly Kogel can supply optional “road” seals or standard “cross” seals to the same bearing in most instances.

Cross seals have slightly more drag but will give you better waterproofing and in most cases are the way to go. Road seals would be great in a race bike or a summer bike and these are the ones that are featured in those videos of the high-speed spinning cranks that most people visualize when thinking about ceramic BBs. I like the fact that these are interchangeable because in theory, you could make a seasonal change when you service your bike.

The BB has a 2 year warranty which isn’t quite as good as the other options but it’s still double (in most cases) that of many of the standard/OE brands. Similarly priced to the Chris King units I think Kogel is a serious contender and the choice might just come down to what suits the bike best.

Our expert review:

Chris King designs and makes their own bearings in-house and that’s been at the heart of everything the company has done to earn its stripes over the years. My own CK unit has been fitted to various bikes over the last few years including a spell on a ‘cross bike so it’s had proper testing! The bearings are completely serviceable and CK has some great videos about how they make bearings and how to service them.

On various bikes, I’ve used lots of different greases in the BB, from long-life in the cross bike to even just oil for a short period in a TT bike. In most cases, a mid-friction high-performance grease works best and is what I’ve used 90% of the time. Initially, Chris King intends there to be very little drag, but due to the way the Angular Contact Bearing works this actually lessens over time – they claim “they get better with age”.

This may raise eyebrows but my unit certainly seems to have rolled with the punches over the years and it’s still behaving. I have experienced a little noise from time to time but I caught this early in each instance and following a full strip and rebuild (including removing and refitting the threaded unit) it always returned to life without an issue. Therefore I’d recommend regular maintenance when using these BBs.

Price wise the CK stainless units sit somewhere in between the CeramicSpeed and C-Bear options, offering a good alternative to both. They also come in a multitude of colours to suit your build.

A bottom bracket for life

Our expert review:

Hope is based in the UK and has been making some of the best products for our climate and riding since they started in their humble Yorkshire workshop. Whilst not primarily thought of as a road brand, Hope makes a full list of suitable products including its excellent BB options.

One of the massive advantages to the Hope unit is the incredibly low price – when you compare it to many of the other options out there, it stacks up very competitively, especially when you consider that you could replace it several times during the lifespan of the more expensive products.

But, will you, therefore, need to be constantly swapping BBs out? Simply, no! They last very well indeed, probably because these products were first and foremost tested on mountain bikes and were always designed to take abuse from both the weather and the terrain.

The BBs won’t spin as friction-free as some of the others on this test, but, as stated, that’s not the point—they’re just very well-made units designed to get the job done. A little grease as part of a normal service is enough to keep them running smoothly, and when they finally give up, they’re much cheaper to replace. They may not be the choice for your TT or race bike, but they're very much worth considering for your all-rounder or gravel bike.

A great affordable replacement for almost any OEM BB

Our expert review:

Similarly to the Hope units, these BBs are designed to get the job done in tough conditions. Along with Hope, these are my go-to units for general replacement and Wheels Manufacturing has a massive range of BBs to suit pretty much any combination.

The ACB stands for Angular Contact Bearing and is similar to what many of the higher-priced units use. This simply means that the bearing is designed to work under load from multiple directions, unlike a standard sealed bearing which only supports load in one axis. This is quite important as many of the cheaper options just use standard bearings.

The units come in a choice of anodized red or black in most cases and look really neat on most bikes. They don’t offer the reduced friction benefits of some of the ceramic options but again that’s not the point – the big benefit is the weatherproofing and the quality, which is similar to Hope. In most cases, they use Enduro bearings which are recognized as the industry's upgrade standard. They are superior in my view to the majority of the standard/OE options.

One of the big positives is the screw-together units that Wheels Manufacturing produce – if you’re getting the dreaded BB creak from a Pressfit BB that’s been fitted badly at some point, the Screw-together style unit can normally solve this – again it does need to be fitted correctly but it can easily resurrect life into an old steed. Like the Hope units, I’d recommend these to anyone wanting a good, solid-performing BB that doesn’t break the bank.

At Cycling Weekly, we are committed to providing top-notch, thorough buying advice and reviews. Our team ventures out on the roads and trails throughout the year, testing the best bikes, clothing, components, and accessories in the toughest conditions.

Putting bottom brackets to the test is not an easy pursuit. Once you are over the hurdle of having fitted between 6 & 8 units to a bike, which could require, as I have mentioned, quite a volume of tools. Testing a bottom bracket needs thousands of miles of riding in all conditions to give the best overview of its quality, durability and performance.

As mentioned several times above, I have been using some of the bottom brackets in this guide for years, so they have certainly been tested.

I cannot count how many bottom brackets I've fitted, replaced, or serviced over the last 20+ years, but I can assure you it’s a considerable number. Additionally, my extensive experience in racing gives me a unique perspective on how those extra few watts can affect your comfort while riding in a group. Any racer will tell you that being at the top of your game requires more than just a few watts, so I also had to put in the hard miles and put all of my components through the ringer.

While racing is no longer my main focus and my own brand, ÆIGHT Bikes, takes precedence, I am also now seeing things from a different perspective. My decisions about matters such as bottom bracket standards directly affect the end user.

Let's start with the point at which you should consider replacing your bottom bracket. With many of the options here, if they are properly maintained, they should last a very long time before wearing out. In general, the BB will start to develop a low, grumbly noise, especially during high-torque pedalling - this may develop into a creak and finally into play.

Some of the options here, like the Hope and Wheels MFG BBs, feature a set of alloy cups into which the bearings are pressed, and it's sometimes possible to replace the bearing rather than the whole unit.

In general, at the first sign of trouble, get the bearings serviced, as this may help avoid the cost of a complete replacement.

It's worth thinking about this as a two-part question: what frame is the BB going in? And, what axle will you be using? The BB is essentially just the bit in between these two things. Some options simply aren't possible due to the size constraints on bearings, but the vast majority are and systems like SRAM's DUB aim to solve the issue of compatibility forever by offering a BB for almost every standard.

Common frame standards are BSA Threaded, Pressfit (41mm), Pressfit 30 (46mm), BB386, T47 and BB30. Some manufacturers like Trek, Cannondale and Cervelo have BB standards that are unique to the brand but some aftermarket brands will still cater for these.

Common axle standards are 24mm, 30mm (for BB30), 30mm (for PF30/386), DUB, GXP and Ultra-torque. Shimano settled on 24mm when they came up with Hollowtech 2 and have used it ever since. Around the same time, Campagnolo settled upon its jointed Ultra-Torque system which it still uses in most instances. SRAM offered three options (BB30/PF30/GXP) for a long time and recently has settled on DUB as their standard. There are still a few SRAM GXP options available where the driveside axle is 24mm and the non-driveside is 22mm!

The concise answer is yes! The full explanation is slightly more in-depth, as it depends on the application or reasoning behind considering a 'better' or more expensive bottom bracket, which introduces some nuance.

A higher-quality finish generally indicates that a bottom bracket is of better quality. This could be due to the quality of the bearing, the accuracy of the bearing seats, or in the press-fit or threaded tolerances. However, this obviously assumes that your frame and chainset have a good finish and accurate tolerances as well.

That is not to say that the standard BB provided with your bike or chainset is rubbish. Shimano offer very affordable and high-quality BBs as standard, and you are unlikely to have issues with them.

As with many components on a bike this depends on three things - maintenance, conditions and usage. For instance, at a cyclocross race, the riders are racing in the sand and having their bikes cleaned with a jetwash, but what you don't see on TV is that it then takes a full day of work to strip and rebuild each bike ready for the next race - bikes are typically treated to a full service 30 times a season! On your home roads, the conditions you'll be riding in are far less severe but the key to making anything last is some regular TLC.

The tricky thing with a BB is you'll need special tools to get to it. This is why, even on a summer bike we would thoroughly recommend using a medium or heavy-weight high-performance grease for the job, which any good mechanic should be able to fit in the bearings. In winter it's worth using long-life grease to help keep the wet and the grime at bay. Even if you have the tools and knowledge to do this you're unlikely to do it very often so always go for a quality grease that's up to the job!

Each manufacturer has specific tools, some of which happen to work for more than one brand. The major tool brands all offer various cup tools to suit the many options, but it's often worth checking if the brand of BB you're buying can sell you the appropriate tool at the same time - they're the experts so they're more likely to sell you the correct tool.

Pressfit BBs require a specific press to fit them and often a specific tool to remove them. Don't ever be tempted to bodge this job as it could easily write off your frameset. The tooling can be expensive so I'd recommend getting your local bike shop or your local mechanic to fit this for you.

What you can learn to do at home, in most instances, is crank removal and basic re-greasing of the bearings. As mentioned above, this isn't a job you'll want to do all the time, but if you can regrease the bearing as soon as you hear any unwanted noise you could save yourself a lot of money in the long run. This also allows you to change the grease you use depending on the season and usage. In many cases to do this job you'll simply need Allen keys, a pick tool and a torque wrench - you could ask you're local mechanic if they can run you through this as a 1-to-1 service the first time you attempt it, or have a look at the manufacturer's YouTube page as many will have tutorials. It's very rewarding to service a BB yourself as you can really feel the difference when you do the job well and it should save you a lot of money over time.

Ceramic is the clear winner when discussing the performance of your bottom bracket. The balls are rounded and generally run smoother because of this. They are less susceptible to heat buildup, which makes them less grease-hungry, and due to their cost, everything else improves as well, such as the bearing race finish and tolerances.

That is not to say they are better for your situation. Steel bottom brackets are generally more serviceable units and, of course, more cost-effective.

It could also come down to how you ride to a degree. Steel bearings managed high loads and torque much better than ceramic units, although this is less so the case with the numbers we are talking about in cycling. However, over time, it could make a difference. So, if you are a grinder, push a big gear or a sprinter, you may find steel more effective. For spinners, those who are lighter on the pedals, there are significant gains to be had from ceramic.